OUR DNA IS RETREADING

As leaders in retreading, we have been actively contributing to reducing consumption and to the reuse of resources for 70 years

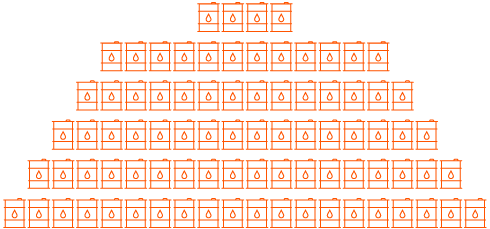

To prefer tyre retreading to its replacement means making an environmentally sustainable choice. A new tyre requires 83 litres of oil, 26 litres are enough to retread it. In addition, the retreading process preserves about 80% of the old tyre and saves up to 70% of energy.

litres of oil required for the production of a new truck and Bus tyre

litres of oil required for the retreading of a truck and bus tyre

69% of oil

saved

At Marangoni Group, we are aware of the fact that, on our planet, linear consumption is reaching its limits and today we must give an answer through a business model that no longer takes its toll on the environment but, instead, values it. This is not about dealing only with an economic change, but also with a cultural change.

Vittorio Marangoni

Marangoni Group Chairman of the Board

DID YOU KNOW THAT…

It takes 100 years for a tyre to degrade

Through retreading, it is possible to extend the life of tyres and therefore considerably reduce their rate of disposal

Thanks to retreading, the following are saved every year

million tons of tyres

are not entered into the environment

billion litres of oil

and other derivatives saved

billion of Euro in the

transportation industry

Estimates calculated by Marangoni SpA based on the data provided by the main tyre retreaders associations

Every year MARANGONI OTR retreads reduce by many thousand tons the use of raw materials such as rubber and steel.This CONTRIBUTES TO CO2 EMISSIONS REDUCTION. For example, four 23.5-25 retreaded tyres for a wheel loader, instead of 4 new tyres, mean approximately 2.500 kg less CO2 emissions in the environment.

2.500

kg of CO2 saved

=

1 year

of emission for 80 sq apartment

marangoni and muse

The Marangoni Group and the MUSE Science Museum: a rather unexpected partnership. The occasion is the exhibition “Extinctions. Stories of catastrophes and other opportunities”, now held at the museum in Trento until 26 June. Why we decided to support this initiative? Because we are experiencing a new era, to say it in the terms used by MUSE: in fact, we are in the midst of a transition from a linear economy to a circular economy, to a more efficient use of the resources of our planet. This is the key transformation that is currently affecting production and consumption patterns worldwide. It is a historical phase in which terms such as “extinction”, in fact, or “catastrophes and opportunities” seem to be quite fitting. And they can be used equally well to take into account some of the transformations that, today, are affecting tyre production and, as a result, also our Group. Keep reading

THE INSTALLATION

The MUSE, Trento Science Museum, knows and estimates the tyre retreading features. This is why it has chosen Marangoni for its Sustainability Gallery.

The set-up offers the possibility to see the difference between a used tyre and a retreaded one and touch with your hands why a good quality product allows for a longer life cycle and – in fact – a considerable saving. The project aims at recalling the proven environmental benefits (retreading reduces 30% of the CO2 emissions and saves 70% of the tyre original materials) and economic (we are talking about savings of up to 35%), reassure the reliability, performance and safety issues of the approved retreaded products. Proof is the fact that, in Europe, 40-45% of the tyres for the transport of freight and passengers are retreaded.